Heat exchangers: Technology and Applications

Heat exchangers are fundamental devices in many industrial processes, designed to transfer heat between two or more fluids at different temperatures without mixing them. The operating principle is based on thermal conduction and convection, allowing the exchange of thermal energy from a hot fluid to a cold fluid, improving energy efficiency and optimizing thermal processes.

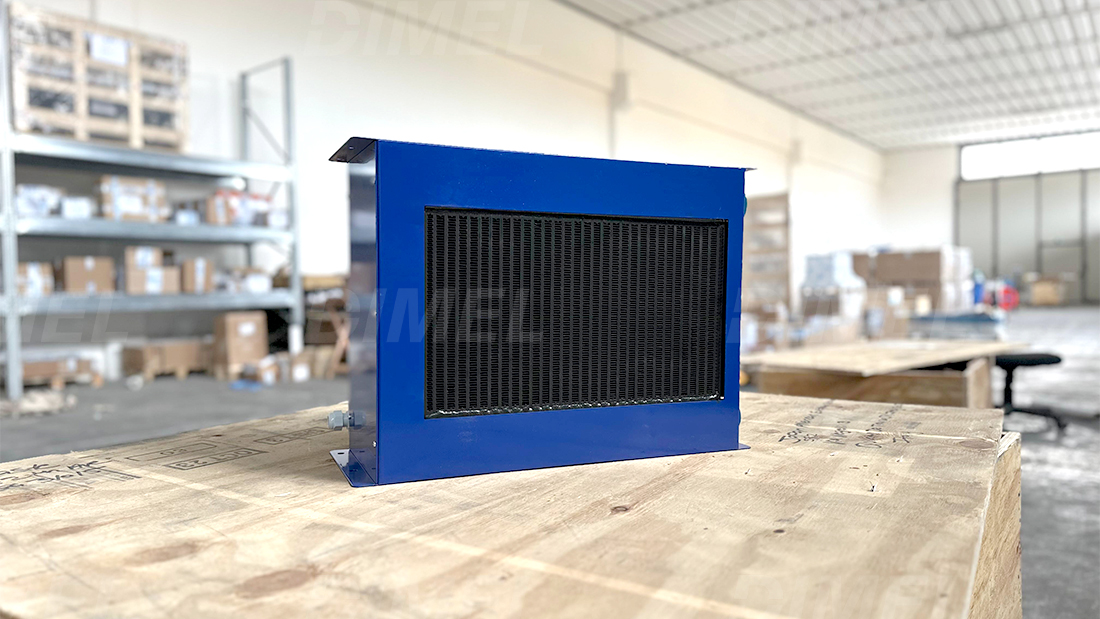

There are various types of heat exchangers, each designed for specific applications and operating conditions. The most common types include plate heat exchangers, shell-and-tube heat exchangers, and double-pipe heat exchangers. Plate heat exchangers consist of a series of thin plates arranged to form channels for fluid flow. Due to their high heat exchange surface area and the ability to be disassembled for cleaning and maintenance, they are particularly suitable for applications requiring frequent maintenance or where fluids may cause fouling.

Shell-and-tube heat exchangers, on the other hand, consist of a bundle of tubes within a cylindrical shell.

One fluid flows through the tubes while the other fluid flows outside the tubes within the shell. This type of heat exchanger is particularly robust and suitable for high pressures and temperatures, making it widely used in the petrochemical industry, refineries, and power plants.

Double-pipe heat exchangers are among the simplest and consist of two concentric pipes, with one fluid flowing in the inner pipe and the other in the outer pipe. Although they are less efficient compared to other types, they are useful in applications where minimal maintenance is required and the operating conditions are not particularly severe.

The sizing and design of heat exchangers require careful analysis of the operating conditions, such as the inlet and outlet temperatures of the fluids, flow rates, thermophysical properties of the fluids, and acceptable pressure losses. The choice of materials is crucial to ensure resistance to corrosion, erosion, and thermal stresses. Common materials include stainless steels, copper alloys, and aluminum, each chosen based on chemical compatibility with the fluids and specific operating conditions.

The efficiency of heat exchangers can be increased through various techniques, such as increasing the heat exchange surface area, adopting counterflow or crossflow configurations, and using finned surfaces.

Counterflow heat exchangers, for example, maximize the temperature difference between the fluids along the entire heat exchange path, improving heat transfer efficiency.

Maintenance of heat exchangers is essential to ensure optimal operation and longevity. Fouling and deposits can significantly reduce thermal efficiency and increase pressure losses. Therefore, regular cleaning operations, inspections, and periodic checks are fundamental, especially in harsh operating environments.

Heat exchangers are used in a wide range of industries, including the chemical industry, food industry, pharmaceutical industry, HVAC (heating, ventilation, and air conditioning), and the energy sector. In industrial applications, they help recover heat from processes, reduce energy consumption, and improve environmental sustainability. In HVAC systems, they are essential for maintaining comfortable environmental conditions and recovering heat in ventilation systems.

In conclusion, heat exchangers are indispensable components for energy efficiency and thermal management in many industrial processes. Their design and maintenance require specific expertise to adapt to operating conditions and ensure optimal performance. Technological advancements and innovations in materials and designs promise

There are various types of heat exchangers, each designed for specific applications and operating conditions. The most common types include plate heat exchangers, shell-and-tube heat exchangers, and double-pipe heat exchangers. Plate heat exchangers consist of a series of thin plates arranged to form channels for fluid flow. Due to their high heat exchange surface area and the ability to be disassembled for cleaning and maintenance, they are particularly suitable for applications requiring frequent maintenance or where fluids may cause fouling.

Shell-and-tube heat exchangers, on the other hand, consist of a bundle of tubes within a cylindrical shell.

One fluid flows through the tubes while the other fluid flows outside the tubes within the shell. This type of heat exchanger is particularly robust and suitable for high pressures and temperatures, making it widely used in the petrochemical industry, refineries, and power plants.

Double-pipe heat exchangers are among the simplest and consist of two concentric pipes, with one fluid flowing in the inner pipe and the other in the outer pipe. Although they are less efficient compared to other types, they are useful in applications where minimal maintenance is required and the operating conditions are not particularly severe.

The sizing and design of heat exchangers require careful analysis of the operating conditions, such as the inlet and outlet temperatures of the fluids, flow rates, thermophysical properties of the fluids, and acceptable pressure losses. The choice of materials is crucial to ensure resistance to corrosion, erosion, and thermal stresses. Common materials include stainless steels, copper alloys, and aluminum, each chosen based on chemical compatibility with the fluids and specific operating conditions.

The efficiency of heat exchangers can be increased through various techniques, such as increasing the heat exchange surface area, adopting counterflow or crossflow configurations, and using finned surfaces.

Counterflow heat exchangers, for example, maximize the temperature difference between the fluids along the entire heat exchange path, improving heat transfer efficiency.

Maintenance of heat exchangers is essential to ensure optimal operation and longevity. Fouling and deposits can significantly reduce thermal efficiency and increase pressure losses. Therefore, regular cleaning operations, inspections, and periodic checks are fundamental, especially in harsh operating environments.

Heat exchangers are used in a wide range of industries, including the chemical industry, food industry, pharmaceutical industry, HVAC (heating, ventilation, and air conditioning), and the energy sector. In industrial applications, they help recover heat from processes, reduce energy consumption, and improve environmental sustainability. In HVAC systems, they are essential for maintaining comfortable environmental conditions and recovering heat in ventilation systems.

In conclusion, heat exchangers are indispensable components for energy efficiency and thermal management in many industrial processes. Their design and maintenance require specific expertise to adapt to operating conditions and ensure optimal performance. Technological advancements and innovations in materials and designs promise