Ball bearings: Technology and Applications

Ball bearings are essential mechanical components used to reduce friction between two surfaces in relative motion, enabling smooth and efficient movement. They are widely employed across numerous industrial sectors, including automotive, aerospace, manufacturing, and various other applications where both radial and axial loads need to be supported.

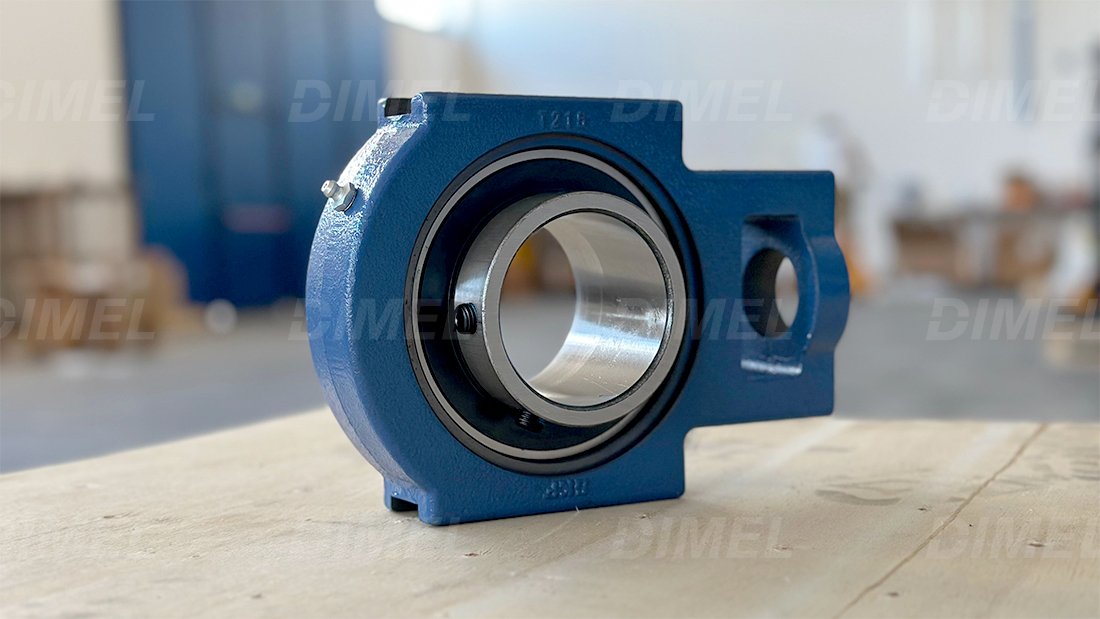

The structure of a ball bearing is relatively simple yet highly efficient. It consists of four main elements: the balls, the inner ring, the outer ring, and the cage that keeps the balls separated. The balls, which are the rolling elements, are placed between two circular rings (inner and outer rings) and rotate with minimal friction. The cage serves to maintain an even distribution of the balls and to prevent direct contact between them, further reducing friction and wear.

Ball bearings operate on the principle of rolling motion, where the balls roll between the races of the inner and outer rings, minimizing resistance to movement compared to the sliding contact that occurs in plain bearings. This allows them to support high loads with low energy dissipation and minimal heat generation, thereby improving operational efficiency and component longevity.

There are different types of ball bearings, each designed for specific applications and load requirements. Radial ball bearings are the most common and are used to support loads perpendicular to the shaft axis. Angular contact ball bearings, on the other hand, are designed to support combined loads (radial and axial) and are often used in high-speed applications such as electric motors and turbines. Four-point contact ball bearings are a variant of angular contact bearings, ideal for applications requiring axial load support in both directions.

Material selection is crucial for the performance of ball bearings. The balls and rings are typically made of high-hardness steel, such as chrome steel, which offers good wear and fatigue resistance. In special applications, materials like ceramics or stainless steel may be used to enhance corrosion resistance and reduce weight.

A fundamental aspect of ball bearings is lubrication, which serves to reduce friction, dissipate heat, and prevent corrosion. Lubrication can be performed using greases or oils specifically formulated for the bearing's operating conditions. The choice of lubricant type and application method depends on factors such as rotational speed, operating temperature, and the type of load applied.

Regular maintenance is essential to ensure the longevity and efficiency of ball bearings. Periodic inspections, cleaning, and relubrication can prevent premature failures and reduce machine downtime. Advanced condition monitoring techniques, such as vibration analysis and oil analysis, can be used to detect early signs of problems and intervene before severe failures occur.

In conclusion, ball bearings are critical components that significantly contribute to the efficiency and reliability of mechanical systems. Their ability to reduce friction and support heavy loads makes them indispensable in a wide range of applications. Continuous innovation in materials and manufacturing technologies promises further improvements in performance, durability, and sustainability.

The structure of a ball bearing is relatively simple yet highly efficient. It consists of four main elements: the balls, the inner ring, the outer ring, and the cage that keeps the balls separated. The balls, which are the rolling elements, are placed between two circular rings (inner and outer rings) and rotate with minimal friction. The cage serves to maintain an even distribution of the balls and to prevent direct contact between them, further reducing friction and wear.

Ball bearings operate on the principle of rolling motion, where the balls roll between the races of the inner and outer rings, minimizing resistance to movement compared to the sliding contact that occurs in plain bearings. This allows them to support high loads with low energy dissipation and minimal heat generation, thereby improving operational efficiency and component longevity.

There are different types of ball bearings, each designed for specific applications and load requirements. Radial ball bearings are the most common and are used to support loads perpendicular to the shaft axis. Angular contact ball bearings, on the other hand, are designed to support combined loads (radial and axial) and are often used in high-speed applications such as electric motors and turbines. Four-point contact ball bearings are a variant of angular contact bearings, ideal for applications requiring axial load support in both directions.

Material selection is crucial for the performance of ball bearings. The balls and rings are typically made of high-hardness steel, such as chrome steel, which offers good wear and fatigue resistance. In special applications, materials like ceramics or stainless steel may be used to enhance corrosion resistance and reduce weight.

A fundamental aspect of ball bearings is lubrication, which serves to reduce friction, dissipate heat, and prevent corrosion. Lubrication can be performed using greases or oils specifically formulated for the bearing's operating conditions. The choice of lubricant type and application method depends on factors such as rotational speed, operating temperature, and the type of load applied.

Regular maintenance is essential to ensure the longevity and efficiency of ball bearings. Periodic inspections, cleaning, and relubrication can prevent premature failures and reduce machine downtime. Advanced condition monitoring techniques, such as vibration analysis and oil analysis, can be used to detect early signs of problems and intervene before severe failures occur.

In conclusion, ball bearings are critical components that significantly contribute to the efficiency and reliability of mechanical systems. Their ability to reduce friction and support heavy loads makes them indispensable in a wide range of applications. Continuous innovation in materials and manufacturing technologies promises further improvements in performance, durability, and sustainability.