Ball valves: Technology and Applications

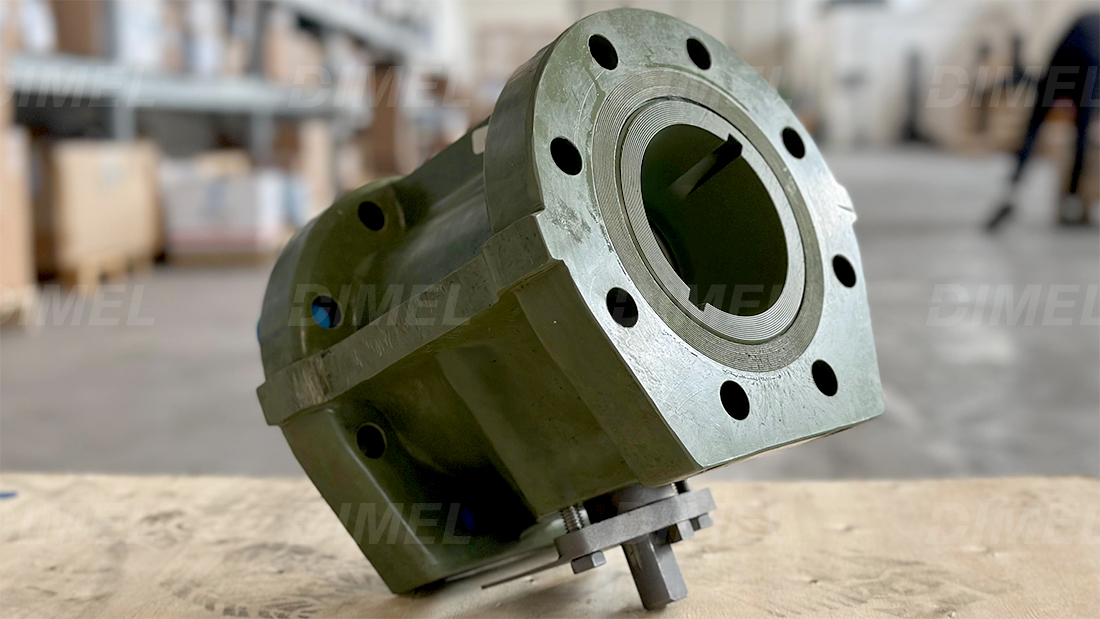

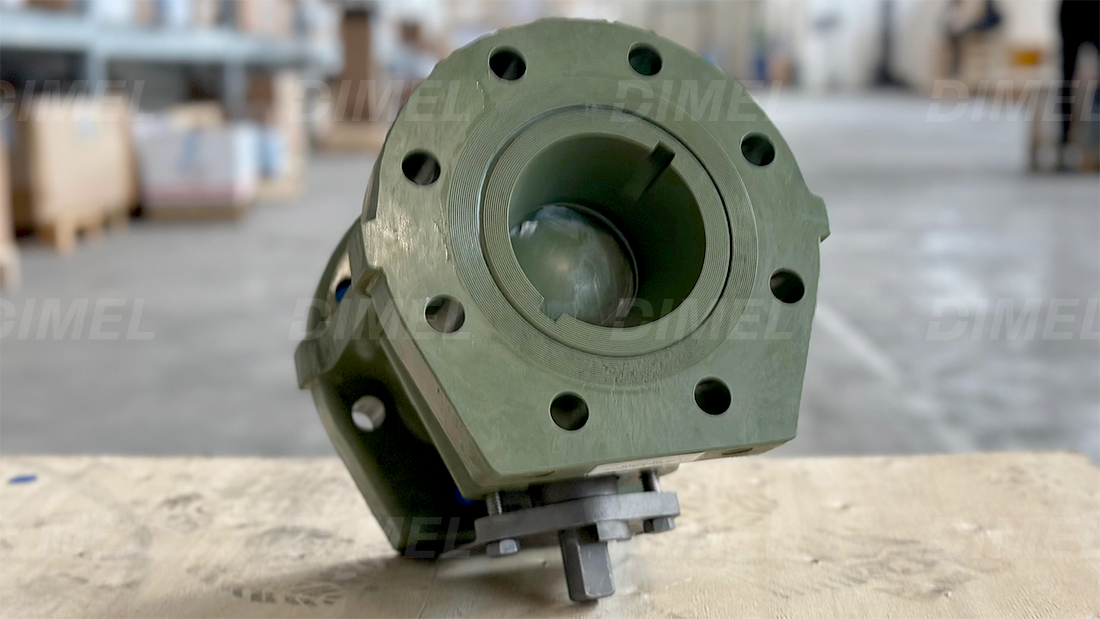

Ball valves are essential components in controlling the flow of fluids across a wide range of industrial and domestic applications. They are widely used for their simplicity, reliability, and ability to provide a tight seal. A ball valve consists primarily of a perforated ball (called the obturator) that rotates within the valve body to control fluid passage.

The operation of a ball valve is relatively straightforward. When the ball is rotated so that the hole is aligned with the inlet and outlet pipes, fluid can flow freely through the valve. When the ball is rotated 90 degrees, the hole is positioned perpendicular to the flow, and the valve closes, blocking fluid passage. This ability to switch quickly from open to closed with a simple rotation makes ball valves particularly suitable for applications requiring rapid and frequent flow control.

Ball valves can be made from various materials, including brass, stainless steel, PVC, and other plastics. The choice of material depends on the specific application, particularly the type of fluid to be controlled and the operating conditions such as temperature and pressure. For example, stainless steel ball valves are commonly used in high-pressure and high-temperature applications, while PVC ball valves are preferred in chemical and hydraulic applications for their corrosion resistance.

One of the main features of ball valves is their ability to provide a tight seal. This is achieved through a combination of a precisely polished ball and seals made from elastomeric or plastic materials like PTFE (polytetrafluoroethylene). The seals ensure that when the valve is closed, there are no fluid leaks. This sealing capability is especially important in applications where preventing the leakage of hazardous or costly fluids is crucial.

Ball valves can be classified based on the configuration of the ball and the valve body. Common configurations include full port ball valves, where the diameter of the ball hole is equal to the internal diameter of the pipe, allowing unrestricted flow, and reduced port ball valves, where the ball hole diameter is smaller than the pipe, causing flow restriction. Three-way ball valves, which have three connection ports, are used to divert flow between different directions or to mix fluids.

Ball valves also offer advantages in terms of maintenance. Their simple and robust construction means they require little maintenance and have a long operational life. Additionally, many ball valves are designed to be easily disassembled, allowing for cleaning and seal replacement without removing the valve from the system.

In conclusion, ball valves are versatile and reliable components used in many applications for controlling fluid flow. Their ability to provide a tight seal, ease of operation and maintenance, and the variety of available materials and configurations make them a popular choice in numerous industrial and domestic sectors. As technologies and industrial needs evolve, ball valves will continue to be a fundamental element in fluid control systems.

The operation of a ball valve is relatively straightforward. When the ball is rotated so that the hole is aligned with the inlet and outlet pipes, fluid can flow freely through the valve. When the ball is rotated 90 degrees, the hole is positioned perpendicular to the flow, and the valve closes, blocking fluid passage. This ability to switch quickly from open to closed with a simple rotation makes ball valves particularly suitable for applications requiring rapid and frequent flow control.

Ball valves can be made from various materials, including brass, stainless steel, PVC, and other plastics. The choice of material depends on the specific application, particularly the type of fluid to be controlled and the operating conditions such as temperature and pressure. For example, stainless steel ball valves are commonly used in high-pressure and high-temperature applications, while PVC ball valves are preferred in chemical and hydraulic applications for their corrosion resistance.

One of the main features of ball valves is their ability to provide a tight seal. This is achieved through a combination of a precisely polished ball and seals made from elastomeric or plastic materials like PTFE (polytetrafluoroethylene). The seals ensure that when the valve is closed, there are no fluid leaks. This sealing capability is especially important in applications where preventing the leakage of hazardous or costly fluids is crucial.

Ball valves can be classified based on the configuration of the ball and the valve body. Common configurations include full port ball valves, where the diameter of the ball hole is equal to the internal diameter of the pipe, allowing unrestricted flow, and reduced port ball valves, where the ball hole diameter is smaller than the pipe, causing flow restriction. Three-way ball valves, which have three connection ports, are used to divert flow between different directions or to mix fluids.

Ball valves also offer advantages in terms of maintenance. Their simple and robust construction means they require little maintenance and have a long operational life. Additionally, many ball valves are designed to be easily disassembled, allowing for cleaning and seal replacement without removing the valve from the system.

In conclusion, ball valves are versatile and reliable components used in many applications for controlling fluid flow. Their ability to provide a tight seal, ease of operation and maintenance, and the variety of available materials and configurations make them a popular choice in numerous industrial and domestic sectors. As technologies and industrial needs evolve, ball valves will continue to be a fundamental element in fluid control systems.