Butterfly valve: Technology and Applications

The butterfly valve is a device used to regulate the flow of fluids, gases, or steam in a piping system. This type of valve is widely appreciated for its simple construction, reliability, and versatility, making it a common choice in many industrial and commercial applications.

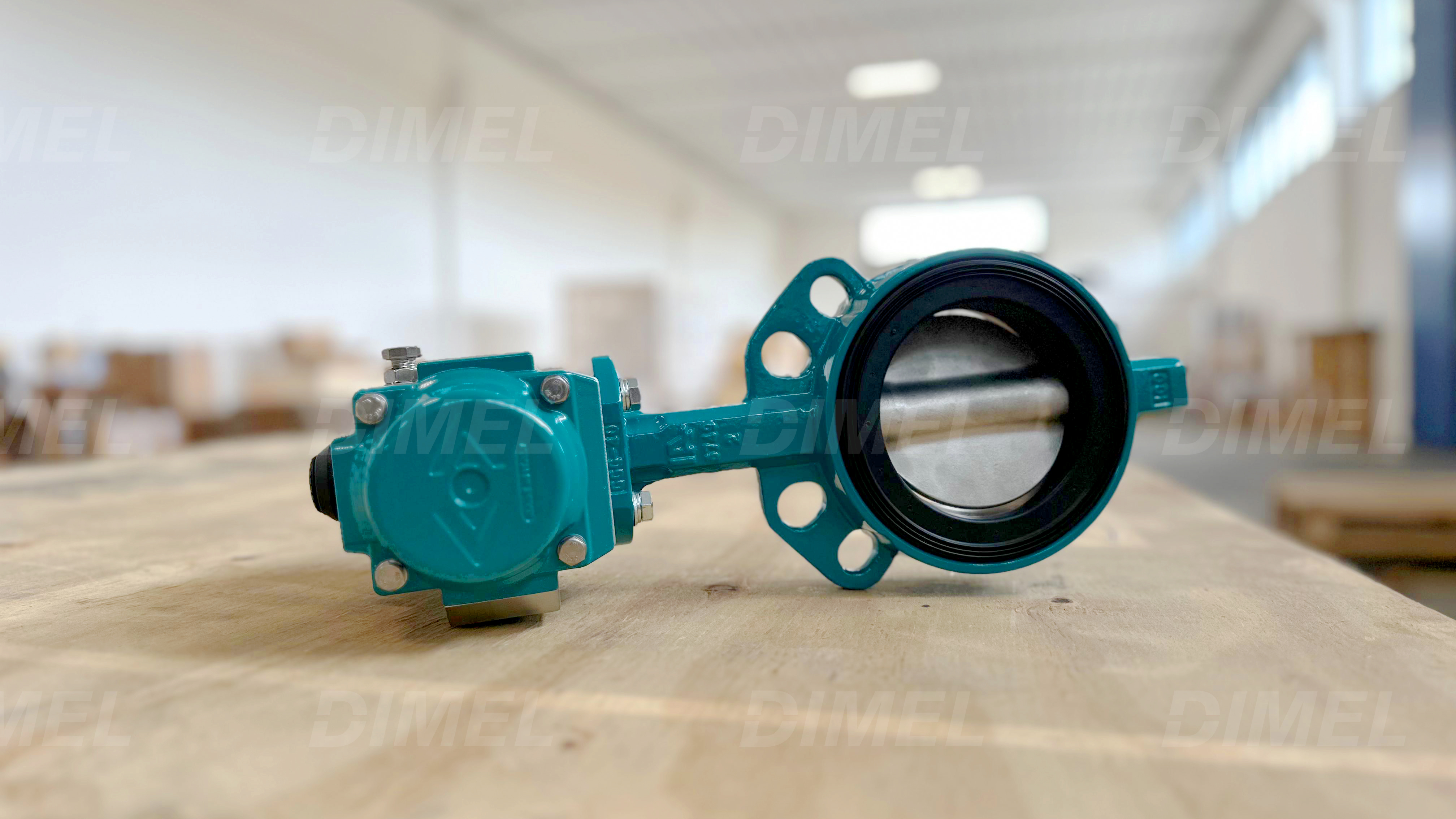

The structure of the butterfly valve is relatively simple. It consists of a cylindrical body that houses a flat or butterfly-shaped disc, mounted on an axis or shaft that passes diametrically through the valve body. By rotating the axis, the disc can be oriented to completely close, open, or modulate the flow of the fluid in the piping system. When the disc is parallel to the flow, the valve is fully open, allowing the fluid to pass freely. When the disc is perpendicular to the flow, the valve is closed, preventing the passage of the fluid.

One of the main features of butterfly valves is their ability to offer precise flow regulation. This makes them particularly useful in applications where precise flow modulation is needed, such as in water management systems, chemical processes, and gas distribution networks. Additionally, butterfly valves have a compact and lightweight design, making them ideal for installation in tight spaces and reducing the overall weight of the piping system.

Butterfly valves can be operated manually, using a lever or handwheel, or automatically, using pneumatic, electric, or hydraulic actuators. Actuators enable remote control and system automation, improving operational efficiency and safety. Furthermore, butterfly valves can be designed with different sealing configurations, using materials such as rubber, Teflon, or metal, to ensure tight sealing and resistance to corrosion and wear.

Butterfly valves offer numerous advantages over other types of valves. Firstly, their manufacturing and maintenance costs are generally lower than those of globe or gate valves. The simplicity of their design reduces the number of components subject to wear, improving reliability and longevity. Additionally, butterfly valves offer low flow resistance when fully open, reducing pressure losses and enhancing system efficiency.

However, butterfly valves are not without limitations. One of the main challenges is the possibility of leakage when the valve is not properly closed, especially in high-pressure applications. Additionally, the valve disc remains in the flow path even when fully open, which can cause turbulence and potential damage to the disc in the presence of abrasive fluids.

In conclusion, the butterfly valve is a versatile and efficient solution for flow control in a variety of industrial applications. Its simple construction, combined with the ability to offer precise regulation and easy installation, makes it a preferred choice in many sectors. Despite some limitations, the advantages offered by butterfly valves far outweigh the disadvantages, making them an essential component in modern fluid management systems.

The structure of the butterfly valve is relatively simple. It consists of a cylindrical body that houses a flat or butterfly-shaped disc, mounted on an axis or shaft that passes diametrically through the valve body. By rotating the axis, the disc can be oriented to completely close, open, or modulate the flow of the fluid in the piping system. When the disc is parallel to the flow, the valve is fully open, allowing the fluid to pass freely. When the disc is perpendicular to the flow, the valve is closed, preventing the passage of the fluid.

One of the main features of butterfly valves is their ability to offer precise flow regulation. This makes them particularly useful in applications where precise flow modulation is needed, such as in water management systems, chemical processes, and gas distribution networks. Additionally, butterfly valves have a compact and lightweight design, making them ideal for installation in tight spaces and reducing the overall weight of the piping system.

Butterfly valves can be operated manually, using a lever or handwheel, or automatically, using pneumatic, electric, or hydraulic actuators. Actuators enable remote control and system automation, improving operational efficiency and safety. Furthermore, butterfly valves can be designed with different sealing configurations, using materials such as rubber, Teflon, or metal, to ensure tight sealing and resistance to corrosion and wear.

Butterfly valves offer numerous advantages over other types of valves. Firstly, their manufacturing and maintenance costs are generally lower than those of globe or gate valves. The simplicity of their design reduces the number of components subject to wear, improving reliability and longevity. Additionally, butterfly valves offer low flow resistance when fully open, reducing pressure losses and enhancing system efficiency.

However, butterfly valves are not without limitations. One of the main challenges is the possibility of leakage when the valve is not properly closed, especially in high-pressure applications. Additionally, the valve disc remains in the flow path even when fully open, which can cause turbulence and potential damage to the disc in the presence of abrasive fluids.

In conclusion, the butterfly valve is a versatile and efficient solution for flow control in a variety of industrial applications. Its simple construction, combined with the ability to offer precise regulation and easy installation, makes it a preferred choice in many sectors. Despite some limitations, the advantages offered by butterfly valves far outweigh the disadvantages, making them an essential component in modern fluid management systems.